High Pressure Rotary Joints are critical components in diverse industrial applications. It enables the controlled transfer of fluids between stationary and rotating elements under demanding pressure conditions.

This article delves into the technical intricacies of High Pressure Rotary Joints, exploring their functionalities, key applications, and crucial considerations for optimal performance, particularly in demanding industrial settings.

Function and Significance

High Pressure Rotary Joints bridge the gap between stationary and rotating components in fluid transfer systems, allowing for uninterrupted flow under elevated pressures.

They are essential in applications where precise and reliable fluid movement is crucial, such as hydraulic systems, steam lines, and industrial manufacturing processes. Their robust design and specialized features ensure efficient and safe operation even in harsh environments.

Applications across Industries

Heavy Machinery

High Pressure Rotary Joints are indispensable in hydraulic systems of excavators, cranes, and other heavy machinery, enabling precise control and power transmission through pressurized fluids.

Steam Applications

They play a vital role in steam distribution systems for power generation, ensuring efficient energy transfer and controlled steam flow at high pressures.

Industrial Manufacturing

High Pressure Rotary Joints facilitate controlled fluid movement in various manufacturing processes, including pulp and paper production, steelmaking, and chemical processing, where precise fluid transfer is paramount.

Energy and Petrochemical Industries

High Pressure Rotary Joints are crucial components in oil and gas exploration and refining processes, enabling safe and efficient transfer of fluids under extreme pressures and temperatures.

Technical Design and Components

Seals

High-performance seals made from materials like PTFE, graphite, or engineered polymers ensure leak-proof operation even under immense pressures.

Bearings

Precision-engineered bearings, often incorporating rolling element or hydrostatic designs, accommodate radial and axial loads while facilitating smooth rotation.

Materials

Robust materials like stainless steel, alloy steel, or specialized polymers are chosen for their strength, corrosion resistance, and compatibility with specific fluids.

Key Considerations for Selection and Use:

Pressure Rating

Choosing the appropriate High Pressure Rotary Joint necessitates careful consideration of the maximum pressure it will encounter during operation.

Media Compatibility

The High Pressure Rotary Joint materials and seals must be compatible with the specific fluids being transferred to prevent degradation or chemical reactions.

Temperature Resistance

Operating temperatures and potential thermal fluctuations must be factored in to ensure material compatibility and long-term performance.

Specific Application Requirements

Additional factors like flow rate, rotational speed, and mounting configurations must be considered to ensure optimal selection and performance.

Maintenance and Longevity

Regular Inspections

Periodic inspections and preventive maintenance are crucial for early detection of wear and tear, ensuring system reliability and preventing unexpected downtime.

Seal Replacements

Timely replacement of worn seals is essential to maintain leak-proof operation and optimal performance.

Manufacturer Guidelines

Adherence to manufacturer-recommended maintenance practices and spare parts ensures optimal lifespan and performance.

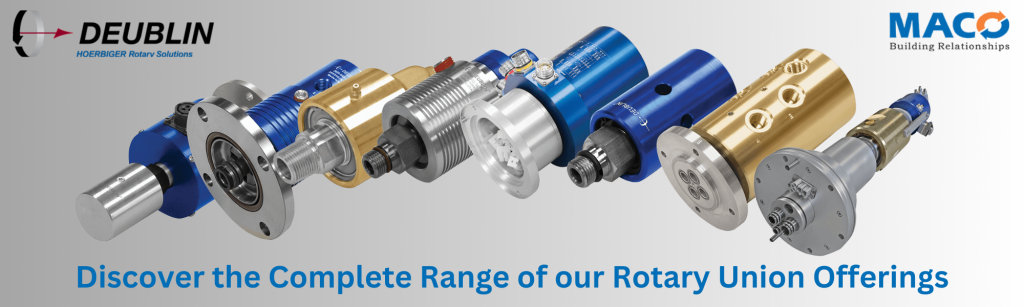

Advantages of Deublin High Pressure Rotary Joint

Let’s talk about the advantages of High Pressure Rotary Joints offered by Deublin.

For example, Deublin 2620-600-252 model, excels in precision fluid transfer for tasks like clamping and unclamping. With two independent passages featuring balanced mechanical seals, this rotary joint ensures extended operational life and reduced torque even under maximum pressure.

Its closed seals provide continuous containment of fluids, ensuring secure and efficient transfer. The addition of dual precision ball bearings enhances operational smoothness, complemented by a labyrinth system for component protection in challenging environments.

Compatible with Deublin 2520 or 1579 series unions, this rotary joint offers versatile application, making it a reliable and efficient solution for industries requiring precise fluid transfer under high-pressure conditions.

Frequently Asked Questions

What is a high-pressure rotary joint, and how does it differ from standard rotary joints?

A high-pressure rotary joint is a specialized component designed to transfer fluids between stationary and rotating parts in industrial machinery, capable of handling elevated pressure levels. Unlike standard rotary joints, high-pressure variants are engineered to withstand and manage increased pressure requirements in various applications.

In which industries are high-pressure rotary joints commonly used, and why are they essential in these applications?

High-pressure rotary joints are commonly employed in industries such as manufacturing, power generation, petrochemical, steel, and hydraulic systems. They are essential in these applications to ensure precise and efficient fluid transfer under elevated pressure, contributing to the seamless operation of critical processes.

What design features make high-pressure rotary joints suitable for demanding industrial environments?

High-pressure rotary joints feature robust seals, precision-engineered bearings, and durable materials to withstand challenging operational conditions. These design elements ensure reliability and longevity, making them suitable for demanding industrial environments.

How do I determine the right pressure rating for a high-pressure rotary joint for my specific application?

The right pressure rating depends on the specific requirements of your application. Consult with the manufacturer or supplier, considering factors such as operating pressure, temperature, and the type of fluid being transferred to determine the suitable pressure rating for your high-pressure rotary joint.

Can high-pressure rotary joints handle different types of fluids, and what considerations should be made for media compatibility?

Yes, high-pressure rotary joints can handle various types of fluids. Considerations for media compatibility include the chemical composition, viscosity, and temperature of the fluid to ensure the selected rotary joint is suitable for the specific application.

What are the key factors to consider when selecting a high-pressure rotary joint manufacturer for my industry needs?

Key factors include the manufacturer’s reputation, experience in producing high-pressure rotary joints, customization capabilities, adherence to industry standards, and their ability to provide efficient customer support and service.

Is regular maintenance necessary for high-pressure rotary joints, and what are the common maintenance practices to ensure optimal performance?

Regular maintenance is crucial for high-pressure rotary joints. Common practices include periodic inspections, seal replacements, lubrication checks, and following the manufacturer’s guidelines for maintenance intervals.

Are there specific safety considerations associated with the use of high-pressure rotary joints in industrial settings?

Yes, safety considerations include proper installation, adherence to pressure and temperature limits, implementing safety protocols during maintenance, and ensuring that all operators are trained on the safe use of high-pressure rotary joints.

How can high-pressure rotary joints contribute to energy efficiency and cost savings in industrial operations?

High-pressure rotary joints can contribute to energy efficiency by ensuring precise fluid transfer, reducing leaks, and optimizing system performance. This efficiency can result in cost savings through reduced energy consumption and maintenance expenses.

Are there innovative advancements in high-pressure rotary joint technology that industries should be aware of for improved performance?

Yes, ongoing advancements in materials, design, and technology aim to enhance the performance of high-pressure rotary joints. Stay informed about innovations such as improved sealing materials, advanced bearing technologies, and enhanced corrosion-resistant coatings for increased durability and efficiency.

High-pressure rotary joints are indispensable components in various industrial applications, enabling controlled and reliable fluid transfer under demanding pressure conditions. Understanding their technical principles, key applications, and selection considerations is crucial for ensuring efficient and safe operation in diverse industrial settings.

As technology advances, High Pressure Rotary Joints continue to evolve with improved materials, designs, and functionalities, solidifying their role as vital elements in the smooth operation of critical industrial processes.

You can talk to our product managers about your specific requirement for High Pressure Rotary Joints. Fill out this form to get a callback from our team.