Our principals

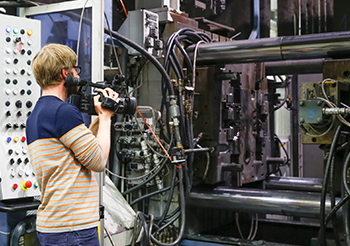

GECSA is a leading manufacturer of Secondary Circuit for Furnaces in Spain. They supply their products to Mill Builders all over the world. Their products are Bus-bar, Water Cooled Cables, Clamps, Flexible, Connections, Isolating pieces and supports. GECSA supplies water cooled cables of any copper cross section, through 10.000 mm2, preferably, rope lay, with only one layer of cable ropes made with 0,5 mm diameter wire. Rope lay type presents the advantages of more flexibility and easier cooling, with a higher overall diameter. This design is the standard GECSA type. GECSA manufacture Water Cooled Cable for Ladle Furnace, Arc Furnace, Induction Furnace etc.

Maco is one of the major suppliers of GECSA products for the Indian manufacturing market. Along with the top-notch products of the company, Maco provides the necessary service support and distribution.

GELENKWELLENWERK, GmBH is the leading manufacturer of GEWES make CARDAN SHAFTS since 1942, located in Stadtilm, Germany. It is among Europe’s most experienced manufacturers of Industrial Cardan Shafts, also known as U-Joints, for a variety of applications. GEWES Cardanshafts are weight-optimised, energy-efficient and high-performaning, developed by using advanced methods and FEM calculations to provide optimal tube wall strengths and diameters for high torsion and bending resistance.

MACO provides its customers the best Cardan Shafts, manufactured by GEWES. Made from tempered steel and case-hardened steel, the calibrated precision steel tubes are used for particularly demanding situations. All materials used fulfil the requirements for marine classification and rail vehicle applications. GEWES Cardan shafts are further characterized by low-maintenance components and low maintenance costs over the entire product life cycle.

GFG is a leading innovator and manufacturer of advanced coil coating equipment, including Roll Coaters, Laminators, Embossers and turnkey Coil Processing Lines. The Peabody line of Electrostatic Oilers has also gained a reputation as one of the most innovative and popular electrostatic coating systems available in the world today. The company’s rich knowledge of the coil processing markets, combined with the ability to leverage technical competencies, experience, and resources provides the foundation to produce a broad range of highly specialized, custom engineered coil coating equipment that meets its client’s critical production requirements.

Maco has been a trusted supplier of GFG Peabody oil coating equipment for its customers in India and back it up with their own services. Leveraging on their well-built network, the company is able to supply GFG products as per the requirements.

Green Project S.r.l. is a world leader in the production and marking of marking systems for the steel and aluminium industry and of fixed and portable automatic character recognition systems. Using the latest technology, Green Project manufactures different types of marking machines covering all applications in the steel industry. Green Project has established a fruitful relationship with the major contractors in the world, including Danieli, SMS Siemag and Siemens VAI as well as end users like Tenaris, Thyssen Krupp, etc.

In India, Maco provides this same high-quality product line of Green Project, to Indian manufacturing companies. As a trusted partner of Green Project, Maco continues to provide the same quality of service to its customers as the parent company. The products find various applications in hot & cold rolled products, including Coil, Plate, Strip, Pipe, Beam Profile / Bar Continuous casting products, Billet / bloom / beamblank and Slab marking.

JAURE and KOP-FLEX are the leading brands of COUPLING being a part of REGAL BELOIT PTS, headquartered in Florence KY. Jaure and Kop-flex specialize in manufacturing customized MILL DUTY COUPLINGS, GEAR SPINDLES, BARREL COUPLINGS & TURBO MACHINERY COUPLINGS. They have manufacturing units in Spain, Slovakia, China, USA, Canada, Mexico and Engineering Centre located in India.

MACO has been a trusted partner for Jaure’s product line and provides the company’s products across various industries, coupled with their own service backing. Jaure Barrel Couplings provide a larger advantage over Gear Coupling in Crane applications, including a higher threshold of radial & axial misalignment, lesser bending stress than gear couplings and more compact drives system. The couplings are used across all major industry segments with optimum efficiency and reliability.

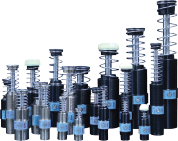

KOBA is the market leader in the deceleration technology, manufacturing SHOCK ABSORBERS, and headquartered in Gasan-Dong, Seoul, Korea. They provide various solutions for shock absorption, anti-vibration and rate control through advanced deceleration technology, constant research & development and reliable quality assurance. Along with high-quality products and lower maintenance costs, KOBA Shock Absorbers increase the life cycle of machinery due to reduction of shock and vibration, while enabling them to work at higher operating speeds and conduct safer operations due to protection of machinery and equipment by reliable and controlled deceleration.

MACO is a trusted supplier of the KOBA manufactured product-range in India and provides customers with highest quality services. The Shock Absorbers provide controlled, predictable deceleration by absorbing the shock and vibration from production facilities, thus, protecting them from destruction, frequent collisions and wearing due to vibration. Along with a dedicated and widespread service and distribution network, MACO helps its customers to receive the best value from these shock absorbers and buffers at the lowest costs.

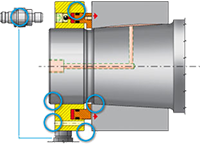

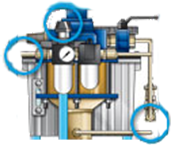

Kamat produce high-pressure pumps up to 1200 kW and 3,500 bar. With only 15 kW, even their smallest pump generates 2,000 bar. The performance spectrum of their plunger pumps is so diverse that the proper pump solution can be developed for every application. The company supplies high pressure Pumps for descaling of Slabs and Billets. Manufacturing of high quality steel for steel slabs and billets demands a fully efficient descaling process. If the descaling process is not carried out properly or is done incompletely, problems arise in the course of the milling since scale remnants are rolled into the steel. KAMAT is meanwhile recognized in some of the largest steel plants worldwide as being a competent manufacturer of pumps and valves.

Maco is one of the biggest suppliers of KAMAT pumps in India, and make the product line available for almost all big manufacturing companies operating in India.

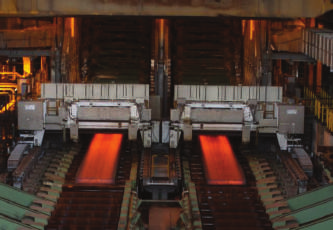

As professional one-stop solution provider, LIAONING MINERAL & METALLURGY GROUP CO., LTD(LMM GROUP) Established in 2007,and focus on engineering research & design, production & delivery, technology transfer, installation & commissioning, construction & building, operation & management for iron, steel & metallurgical industries globally. LMM GROUP supply raw material, spare parts & equipment, technology transfer, import & export, international EPC projects, etc., mainly for metallurgical industry in over 30 countries & areas in Southeast Asia, Japan, Africa, America, European markets, etc., forms stronghold and core competitiveness in steel melting, continuous casting, rolling areas to deliver value-add innovative products and service and one-stop solution to global customers in iron, steel, metallurgical industries etc.

Maco brings this varied range of LMM products to the Indian manufacturing market and provides all the sales and support services in India.

L-TEC Steel Industry Products is a world-leading manufacturer of mechanized scarfing machines, heavy industry cutting machines, and other related equipment. Although L-TEC Scarfing Machines form the greater part of L-TEC’s steel industry products and business, a number of other steel mill related products are included.

Maco is the trusted supplier of L-Tec products for its Indian customers.

Luoyang Bearing Corp. (Group) is the biggest comprehensive bearing manufacturer in China. They are specialized in the export of Chinese Bearing Goods. Its product covers 10,000 sizes, 9 categories in all precision tolerance classes. They manufacture various types of ball and roller bearings with bore from 8mm up to max OD of 11 meters according to the ISO9001 standard, Qs9000 standard and China National Standard. The lightest bearing weighs only 25.4 grams and the heaviest one weighs 15 Tons. Their yearly output volume is 150 million pieces.

Maco provides the LYC product range to Indian companies and support it with their own distribution and service network for an unmatched experience.

Metalltechnik Schmidt has produced Ferrosad low carbon shot for over 50 years combining the basic elements of fire and steel to produce their products. Only the highest quality of raw materials are used which, combined with an in-house expertise gives a superior abrasive. A continued investment in modern technology combined with consistent attention to customer’s needs aids the company in delivering the perfect surface finish.

Maco is the partner in India for the company to provide its products, along with proper distribution and any service required.

Miebach Laser Welding machines are the world standard for coil joining among international steel companies. Low cycle time, no over-thickness and minimal material structural change are the result of years of experience and continuous design improvements engineered into our laser welding machines. Through continuous development and innovation, the company guarantees fast and reliable production through solutions that are individually tailored to customer needs.

Maco provides the company’s laser welding machines to its client base in India, along with proper distribution and timely servicing.

SAIZAR Strapping Machines is a company specialized in supplying all kind of strapping solutions for the metal, graphite, agricultural, lumber and construction industries. They design and manufacture all kind of solutions bearing in mind customer’s needs as well as their plant circumstances, exploring all the possibilities and considering the best options, in order to offer the customer a customized solution which satisfies their needs.

MACO is the preferred supplier for its clients in India, to provide them with Saizar product range, as well as look after its distribution and services.

Saldotecnica Ligure has been pioneer in oxy- cutting technology for last 70 years. Their oxy –cutting machines are installed all over the world. Their philosophy is oriented towards quality products, process efficiency and full customer satisfaction. Their system is compatible with that of other manufactures. To date Saldotecnica can boast of almost 1000 plants sold all over the world, some of them still working after 40 years of operation.

Maco is the proud supplier of Saldotecnica products for companies functioning in India. They also provide the necessary ancillary support and services to clients as required from time to time.

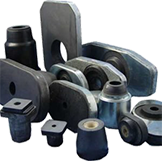

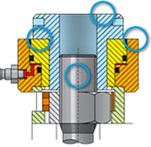

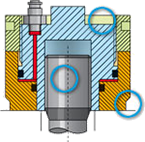

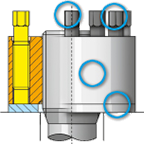

SCHAAF is a reputed German multinational Company has more than 30 years’ experience in the field of Hydraulic Bolt tensioners, Oil Press Fit equipment and hydraulic Couplings. SCHAAF not only just produce basic tools, but also Hydraulic tensioners with special options like Spring return, Load limiter, Stroke limiter & Customized solutions like elongation measurement, load measurement and complete documentation system.

Maco uses its widely distributed network and provides all product of the company to its customers in India. Maco also looks after the servicing and maintenance support for the clients.

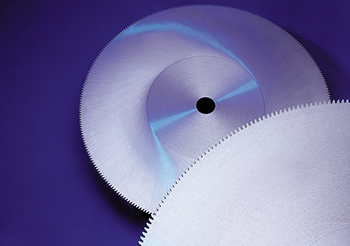

Sheffield Industrial Saw provide products for every type of industrial cutting application for the customers both UK based and Worldwide. SIS have a dedicated manufacturing plant in Sheffield employing an array of experienced staff with a shop-floor workforce who can boast a combined experience of over 900 years in the manufacturing of the highest quality circular saw blades. Their product range extends across Segmental, Tungsten Carbide tipped and solid High Speed Steel circular blades as well as being official distributors for the Do-All bandsaw blade. The company also supply blade repairing machinery.

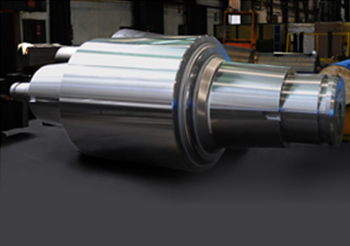

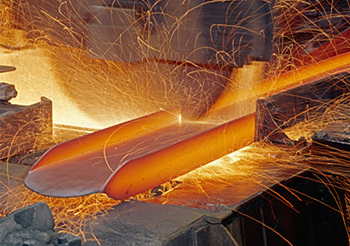

M/s. Sidenor Forgings & Castings S.L., Spain is a world renowned manufacturer of Rolls for Rolling Mill. They have been supplying forged Rolls for Rolling Mill to the Mill Builders as well as to the Steel plants since 1964. M/s. Sidenor is an ISO 9001:2008 Certified Company.

Maco has been a very trusted partner for Sidenor products and provide their entire product range for their clients in India.

POWER MnC Co., Ltd. established in 1983, has developed technologies in field of physical measurement and structural safety, being Korea's leading manufacturer of industrial measuring, control and condition monitoring system. Through our various experiences, we have successfully developed high-tech technologies such as caster strand monitoring system, multi-component load cells, industrial weighing system and R&D equipment including data acquisition system and analysis software, and honorably validated through field applications.

POWER MnC also provides professional test engineering and safety evaluation service for power plants, civil constructions, aircraft and automobiles, etc. In consequence of them, we have expanded the limit of measurement and control system.

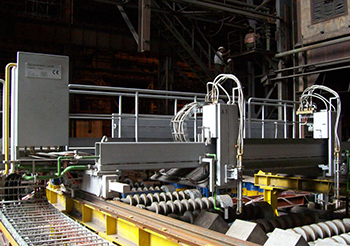

Saldotecnica has been the pioneer in oxy-cutting technology since 1970. Their oxy-cutting machines are installed all over the world. They are also a supplier of various products of steel melting shop and caster. All the projects are executed on turnkey basis and after sales service support is provided.

Product Range:

• Oxy-cutting machines for CCM-(Slabs, blooms, rounds, beam-blanks and billets)

• Length measuring systems for CCM

• Oxygen lance holders

• Ovens for snorkels heating

• Burners and lances for furnaces

• Ladle and tundish heating/drying stations Regulators etc.

• Shape cutting machines for plates by plasma/flame

• Iron powder injection system for high alloyed or stainless steel cutting

• Spares for Oxy cutting machines like Torches, Nozzles, and Pressure

• Manual torches for heavy cuttings up to 1000 mm thickness

KRENN is synonymous with high-quality and user-oriented cutting tools for safe, effortless and economic cutting of steel since 1947. They provide tools for a long working lifespan. They expanded the steel cutter range with innovative tools and devices, so that today they can offer cutting devices of all types with different drives: manual, electro-hydraulic, battery-powered, hydraulic and pneumatic.

In 2015, high-quality hydraulic KAMAX steel cutters, straighteners and testing presses also joined their product range.

Centro-Metalcut is an industry innovator and a leading manufacturer of highest quality conditioning grinders and abrasive saw machine for the steel industry. They custom engineer the equipments to fit the specific application. They design, build and test the machine at their plant which reduces installation and startup time.

Product Range & Major Application Areas For Grinding Stainless Steel, Special Alloys & Carbon Steel Products:

• Stationary Conditioning Grinders (for Slabs, Billets or Bloom and Rounds)

• Track Conditioning Grinders (for Billets or Bloom, Small Slabs, Rounds)

• Overhead travelling grinder (Spot Grinder)

• Dry Cutting Gantry Abrasive Saw Machines (Rails, Angles, Channels, etc.)

• Dry Cutting Pivot Abrasive Saw Machines (Rails, Angles, Channels, etc.)

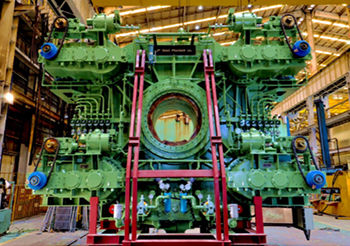

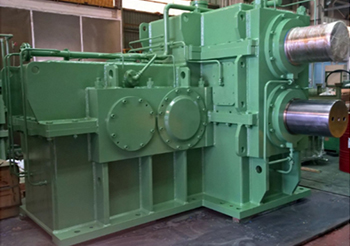

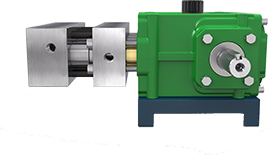

Established in 1980, FORMOSA is the market leader in the production of customized GEAR BOXES, having license from Renk Tacke, Germany. Equipped with state-of-the-art machine tools, FORMOSA GEAR PLANT, based in Taiwan is a part of Formosa Heavy Industries Corporation (FHI Group). It is renowned worldwide for manufacturing both Reducers and Increasers and supplies a wide range of products for various industries including Cement, Steel, Petrochemical, Paper, Sugar, Rubber and Plastic, to name a few.

MACO provides its expertise and services, along with the product range offered by Formosa, to its customers. Being a trusted partner for Formosa, the company helps in reaching out to the farthest corners of India through their own well-connected distribution network. Formosa Gear produces and supplies gearing products designed for maximum reliability and performance.

Fog, covering the earth, growing forests and moistening the air, has always been closely related to our lives. Crops essential to our life grow by absorbing moisture from the air, as well as their roots. Fog plays a part in converting undergrowth and fallen leaves into organic fertilizer. Additionally, textile production’s weaving techniques were developed in areas near rivers, because the river’s fog produced the proper humidity needed. Today, fog plays an important role in quality improvements of electronic device manufacturing and printing. Fog serves to improve the global environment, from combating global warming, to dust pollution control. It is our mission to design and provide high-quality fog spraying systems to contribute to our industries, and to mankind.

MACO provides its expertise and services, along with the product range offered by ikeuchi, to its customers. Being a trusted partner for ikeuchi, the company helps in reaching out to the farthest corners of India through their own well-connected distribution network. ikeuchi Industrial Spray Nozzle and Humidification System designed for maximum reliability and performance.

.png)