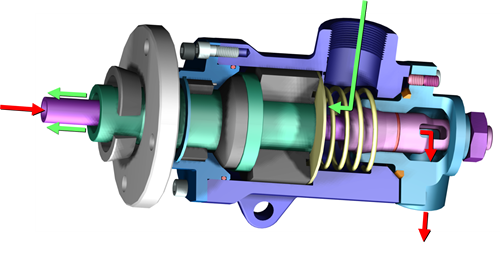

Rotary unions play a vital role in facilitating fluid transfer between stationary and rotating parts in various machinery applications. In this blog, we’ll take a straightforward look at the essential components that make rotary unions functional and reliable, and explore the unique advantages of Deublin rotary union parts.

Housing: The Outer Casing

The housing, typically crafted from durable materials like stainless steel or brass, is the outer casing that provides structural support and protection for the internal components. These parts offer superior durability and corrosion resistance, making them a preferred choice in demanding industrial environments.

Shaft: The Rotating Component

Crafted from robust materials, the shaft is the central rotating component responsible for transferring fluid between stationary and moving parts. Deublin rotary union parts are renowned for their precision engineering, ensuring a smooth flow of liquids and minimizing wear and tear over time.

Seals: Leak Prevention

Seals, such as O-rings, lip seals, and mechanical seals, are critical in preventing fluid leakage between stationary and rotating parts. Deublin rotary union parts, with their advanced sealing technology, create a secure barrier that surpasses industry standards, ensuring a controlled and efficient flow of liquids.

Bearings: Friction Reduction

The importance of bearings lies in supporting the rotating shaft and reducing friction for smooth rotation. The rotary union parts, equipped with high-performance bearings, not only contribute to efficiency and longevity but also outperform competitors in rigorous industrial applications.

Ports: Fluid Entry and Exit

Ports serve as entry and exit points for fluids, strategically placed to allow controlled fluid flow. Deublin rotary union parts are designed with precision-machined ports, ensuring optimal fluid dynamics and surpassing standard industry requirements.

Internal Passages: Guiding the Fluid

Internal passages guide the fluid from the inlet to the outlet, forming a pathway for a precise and uninterrupted flow. The design passage ensures that internal passages are precisely engineered, maintaining a smooth and efficient flow unmatched by other alternatives.

Retention Mechanism: Securing the Union

A robust retention mechanism ensures the rotary union stays in place during operation, preventing unexpected detours and ensuring consistent performance. Deublin rotary union parts feature an advanced retention mechanism, providing stability and reliability in the most demanding industrial environments.

Mounting Flange: Attachment Point

The mounting flange, a crucial attachment point, provides a means to attach the rotary union securely to the equipment. Deublin rotary union parts, with their superior design and construction, ensure proper alignment, stability, and ease of installation, setting them apart from other options.

Lubrication System: Ensuring Smooth Operation

Some rotary unions come equipped with a lubrication system to ensure smooth rotation, minimize wear, and prolong the life of the union. The parts of our unions, integrated with an advanced lubrication system, go the extra mile to ensure optimal performance and longevity.

Material Selection: Choosing the Right Materials

Materials like stainless steel, brass, and polymers are chosen based on the type of fluid and environmental conditions, ensuring durability and optimal performance. Make sure that the rotary union parts stand out with their meticulous material selection, providing unmatched performance in various operating conditions.

Frequently Asked Questions

What is a rotary union?

A rotary union is a mechanical device facilitating fluid transfer between stationary and rotating parts, commonly used in various machinery applications, with Deublin rotary union parts offering superior performance and durability.

Why are rotary unions important?

Rotary unions are crucial for applications requiring controlled fluid transfer between stationary and rotating components, preventing leaks and ensuring machinery efficiency. Deublin rotary union parts play a significant role in enhancing these key functions.

What are the main components of a rotary union?

Key components include the housing, shaft, seals, bearings, ports, internal passages, retention mechanism, mounting flange, lubrication system, and carefully selected construction materials.

How do seals prevent leakage in rotary unions?

Seals, such as O-rings and lip seals, create a secure barrier between stationary and rotating parts, preventing fluid leakage during operation. Deublin rotary union parts are recognized for their advanced sealing technology, ensuring superior leak prevention.

What materials are commonly used in rotary unions?

Stainless steel, brass, and various polymers are commonly used based on the type of fluid and environmental conditions, ensuring durability and optimal performance. Deublin rotary union parts stand out with their meticulous material selection and engineering.

Why are bearings important in a rotary union?

Bearings support the rotating shaft, reducing friction and ensuring smooth rotation, contributing to the overall efficiency and lifespan of the rotary union. The parts of rotary union supplied by us are equipped with high-performance bearings, offering unmatched reliability in industrial applications.

What is the purpose of the lubrication system in a rotary union?

The lubrication system keeps the rotating parts well-lubricated, minimizing wear and tear and contributing to the smooth operation and longevity of the rotary union. Deublin rotary union parts, integrated with an advanced lubrication system, set a benchmark for optimal performance.

How are rotary unions installed?

Rotary unions are typically installed by attaching the mounting flange to the equipment, ensuring proper alignment for consistent performance. Deublin rotary union parts simplify the installation process with their superior design and construction.

Can rotary unions handle different types of fluids?

Yes, rotary unions are versatile and can handle various types of fluids, including liquids and gases. Material and seal types are adjusted based on the specific fluid being transferred..

Are rotary unions maintenance-free?

While designed for durability, regular maintenance, including lubrication checks and seal inspections, is recommended to ensure optimal performance and longevity. Deublin rotary union parts, with their robust design, minimize the frequency of maintenance requirements.

What applications commonly use rotary unions?

Rotary unions are widely used in manufacturing machinery, hydraulic systems, rotary tables, printing presses, and any equipment requiring fluid transfer between stationary and rotating parts. Deublin rotary union parts are preferred in critical applications demanding precision and reliability.

Can rotary unions handle high-pressure fluids?

Yes, rotary unions can be designed to handle high-pressure fluids, with the choice of materials and construction tailored to the specific pressure requirements of the application. Selecting Deublin rotary union parts meeting the system’s pressure specifications is crucial for optimal performance.

Conclusion

To sum it up, Deublin rotary union parts are like the superheroes of machinery. They make sure fluids move smoothly between stationary and moving parts, thanks to their strong and smart design. Whether it’s the tough outer casing, the spinning shaft, or the special seals that stop leaks, each part plays a crucial role in keeping things running smoothly. Deublin’s parts are like the champions of the machinery world, standing out for their top-notch quality and making sure everything works efficiently for a long time. So, if you want your machinery to be a superhero too, choose Deublin for a future where things move smoothly and last a really long time.