The Water Rotary Union is crucial for smooth water and fluid flow in machinery. It plays a vital role in various industrial applications for seamless operations.

In this comprehensive guide, we’ll explore the details of water rotary unions, also called rotary joints for water. These engineering solutions play a crucial role in different industries, from general manufacturing to high-pressure applications, continuous casting, and adhering to strict standards in the food and pharmaceutical sectors.

From high-pressure cleaning to delicate cooling applications, rotary joints for water adapt to diverse needs, offering a wide range of sizes, materials, and configurations.

Explore our full range of water rotary unions and other unions on our product page.

What is a Water Rotary Union?

Water rotary union serves as a vital component facilitating the transfer of water or other fluids between a stationary source and a rotating machine part. Their primary function is to prevent leaks and ensure a consistent flow of fluid, facilitating efficient cooling, lubrication, and various manufacturing processes.

In other words, the precision-engineered rotary joint for water enables the unrestricted rotation of water-carrying components, preventing kinks or disruptions in fluid delivery.

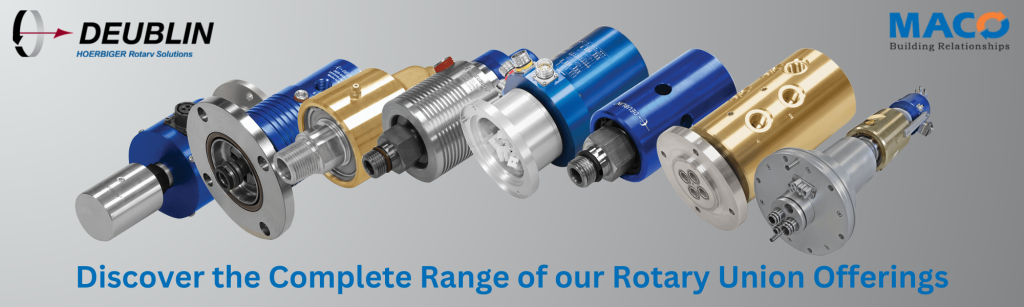

Versatility and Customization: Deublin’s Offering

Now you are aware that a rotary joint for water facilitates seamless water transfer in rotating machinery, ensuring a constant and efficient flow within industrial applications. But do you have any idea about Deublin’s advanced offerings? Let’s delve deep.

Deublin’s water rotary unions offer a wide range of sizes, ensuring adaptability to any application. From low-speed to high-pressure operations, these rotary unions are engineered to handle various specifications for water or other media. Collaboration with our experts allows for customized configurations that best suit the specific needs of each water application.

General Industry Applications

57 Series

Deublin’s 57 series stands out in general industry applications, designed to handle wear and challenging water conditions. Configurations for monoflow and duoflow, coupled with a simple design for quick seal replacement, make it a versatile solution.

755 Series

This series, available in monoflow or duoflow configurations, extends seal life 2 to 4 times with Extended Life Sealing (E.L.S), making it suitable for water applications where filtration might not be possible.

6200-6400 Series

Specifically designed for easy seal replacement on the machine, this series operates in high temperature and poor water quality conditions. Available in monoflow and duoflow configurations ranging from 2″ up to 4″.

F Series

In the F Series, the 5″ water rotating union enables on-machine seal replacement, offering convenient repair and minimizing downtime.

High-Pressure Solutions

927 Series

For applications requiring high pressure, high speed, and low torque, the 927 series is a reliable choice. Engineered with a mechanism directing water away from bearings, it ensures robust performance in demanding conditions.

AP Series

Deublin’s high-pressure and high-speed water rotary union boasts balanced mechanical seals crafted from tungsten carbide, ensuring smooth rotation and resistance to seal wear. The AP series can handle capacities up to 1″ and comes pre-lubricated for a lifetime of use.

D Series

The D series, designed to withstand very high pressure and accommodate angular movement, utilizes materials suitable for water but can be adapted for other fluids. Widely applied in tasks such as hose winders, it excels particularly under pressure.

ZAP Series

The ZAP series, a larger counterpart to the AP series, boasts an impressive pressure rating of up to 1100 bar (almost 16,000 psi). It is especially well-suited for applications like parts washers.

Low-Speed Operations

Type C Bronze

In low-speed scenarios, the Type C Bronze series excels with carbon bearings for enhanced strength and shock resistance.

The seal wear indicator in the system enables scheduled maintenance, leading to decreased downtime and enhanced productivity.

Plane Swivel

Deublin’s plane swivel, featuring a streamlined three-piece design, facilitates the conveyance of various fluids, ensuring easy installation, repairs, and maintenance.

Self-Aligning Swivel

Available in an array of sizes, the Deublin self-aligning swivel is capable of handling angular flexibility and articulating piping applications for water. Its positive sealing design prevents hose failures and leaks, thereby reducing the need for maintenance.

22 Series

Operating within the car wash industry, the 3/4″ stainless steel rotary union in the 22 Series features a monoflow design with silicon carbide seals. These seals effectively minimize early wear and downtime.

Continuous Casting Innovations

2400 Series

Specifically designed for continuous casting, the single passage rotary union made of brass and stainless steel features balanced mechanical seals to extend its life and reduce downtime.

M60 Series

Also known as a bearing-less CCM union, the M60 Series conveys water through the frame of the machine rather than hoses, innovatively changing the approach to fluid transfer in continuous casting.

2400 Duoflow Series

Customizable for various mounting configurations, the duoflow rotary union is tailored to optimize performance in continuous casting applications. This design minimizes leakage and enhances overall efficiency.

D60 Series

In the D60 Series, water circulates in and out from one side of the machine, necessitating a siphon tube for uniform cooling. This feature makes it well-suited for continuous casting processes.

Food and Pharmaceutical Excellence

54 Series

Recognizing the unique requirements of the food and pharmaceutical industries, Deublin offers the 54 series made of corrosion-resistant 316 stainless steel. And it can withstand a very high temperature.

157 Series

A 1/2″ water union is designed to handle severe water conditions, making it an essential component in food and pharmaceutical manufacturing.

What makes Deublin’s Water Rotary Union special?

Mechanical Seals and Advanced Technology

At the heart of rotary unions lies the mechanical seal—a rotating connection crucial for preventing leaks. Deublin Rotary Unions stand out with advanced sealing technology, significantly reducing downtime and maintenance costs associated with leaking unions. This emphasis on reliability and durability makes them indispensable in various industrial settings.

Enhancing Efficiency in Water Applications

Beyond preventing leaks, water rotary unions contribute significantly to enhancing efficiency in water applications. Their precise engineering allows for optimized water flow, ensuring that machinery operates at peak performance. This increased efficiency translates to energy savings and overall cost-effectiveness in industrial processes.

Advancements in Materials and Design

As technology progresses, water rotary unions continue to benefit from advancements in materials and design. Modern materials, such as advanced polymers and composite alloys, enhance the durability and resistance of rotary unions to varying environmental conditions. Additionally, innovative design features improve the overall lifespan and performance of these crucial components.

Frequently Asked Questions

Q1: Where can I purchase Deublin rotary unions for water applications?

A: Choosing the right rotary joint for water requires careful consideration of factors like pressure, temperature, flow rate, and the type of rotating equipment it will be paired with.

Deublin’s water rotary unions are available through authorized distributors globally. And Maco Corporation is the sole partner for all the water rotary unions of Deublin in India.

Q2: How do I determine which series of rotary unions are most compatible with my specific industrial application?

A: Maco Corporation offers a dedicated team of experts to assist you in selecting the most suitable water rotary union for your specific needs. You can reach out to our customer support team by email or call for personalized guidance based on your industry and application requirements.

Q3: Can Deublin provide customized rotary union solutions based on specific industry needs?

A: Yes, Deublin offers customization services to tailor rotary unions to unique industrial requirements. For inquiries about custom configurations, please contact our technical team via email or phone.

Q4: Are there specific technical specifications available for each series of rotary unions?

A: Yes, detailed technical specifications for each series, including pressure handling and speed requirements, are available on our official website. You can also contact our technical support team for any additional information.

Q5: What is the pricing range for Deublin rotary unions?

A: Pricing varies based on the series and features. For detailed pricing information, please contact our sales team through email or visit our website for general pricing guidelines.

Q6: Do Deublin rotary unions comply with international standards for industrial equipment and safety?

A: Yes, Deublin Rotary Unions adhere to rigorous international standards for industrial equipment and safety. Certifications validating the quality and safety of our products are available upon request. Thanks to their ingenious design and robust construction, rotary joints for water offer a reliable and cost-effective solution for transferring water in countless applications

Q7: What kind of maintenance is required for Deublin rotary unions?

A: Deublin rotary unions are designed for minimal maintenance. Regular maintenance is key to keeping your rotary joint for water in top shape. Inspecting for leaks, wear, and proper lubrication ensures smooth operation and extends its lifespan.

Q8: Is the investment in Deublin Water Rotary Union justified by efficiency gains in industrial processes?

A: Absolutely. Many industries have experienced significant efficiency gains and reduced downtime using Deublin water rotary unions. The initial investment is justified by long-term benefits in process optimization and reliability. For case studies or specific testimonials, please visit our website or contact our sales team.

Conclusion

Deublin’s rotary unions for water applications epitomize adaptability, reliability, and efficiency in diverse industrial settings. As businesses strive for process optimization, exploring the versatile range of Deublin rotary unions becomes a strategic imperative. With their ability to handle demanding environments and diverse water needs, Deublin rotary joints for water are truly an important item of the fluid transfer world

Whether in general industry, high-pressure operations, low-speed applications, continuous casting, or demanding sectors like food and pharmaceuticals, Deublin stands as a reliable partner in elevating industrial fluid transfer processes. It’s not just about rotary unions; it’s about optimizing the heartbeat of industrial operations for sustained success.